Industrial Bulk Plastic Containers: Innovations Driving Efficiency

Wiki Article

Why Mass Containers Are Necessary for Simplifying Your Supply Chain and Enhancing Effectiveness

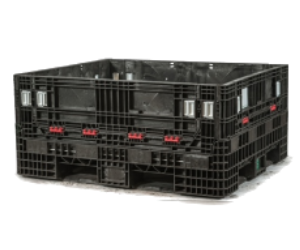

Bulk containers play an important duty in enhancing supply chains. Their style boosts storage performance and lowers packaging waste. Services benefit from boosted stock management and streamlined transport processes. As firms go for cost-effectiveness and sustainability, the fostering of bulk containers comes to be increasingly pertinent. However, the effect of these containers expands past mere logistics. Comprehending their more comprehensive ramifications discloses significant chances for functional improvement. What are the particular advantages that make them important?The Advantages of Bulk Containers in Supply Chain Administration

Several businesses rely on conventional packaging methods, the advantages of bulk containers in supply chain management are increasingly recognized. Bulk containers provide enhanced performance by optimizing storage room and reducing the regularity of deliveries. Their standard dimensions assist in much easier handling and transport, leading to streamlined logistics processes. Moreover, these containers provide superior protection for items, lessening the danger of damages throughout transit. By utilizing mass containers, business can also boost stock management, as they permit for much better tracking and control of supply levels. In addition, using bulk containers can lead to boosted functional adaptability, enabling companies to adapt to modifications in need better. In general, mass containers represent a tactical benefit in modern supply chain techniques.Cost Financial Savings Through Lowered Packaging and Waste

Bulk containers substantially contribute to set you back savings by lessening product packaging materials and lowering waste. By utilizing bulk containers, organizations can significantly lower the amount of packaging needed for transferring items, which leads to decrease material costs. In addition, this reduction in packaging not just minimizes expenses yet additionally lessens the ecological effect connected with waste disposal - Shop Bulk Plastic Containers. With fewer products to take care of, business can enhance their procedures, improving overall operational effectiveness. The space-saving design of mass containers also allows for boosted transportation logistics, further contributing to decreased shipping costs. Eventually, embracing bulk containers cultivates a much more cost-effective and sustainable strategy to provide chain monitoring, making it possible for organizations to assign sources more properly and boost their profits

Enhanced Inventory Monitoring With Mass Storage Solutions

Bulk storage remedies supply significant benefits for inventory management by optimizing space usage and improving supply tracking processes. By combining inventory right into less, larger containers, companies can make best use of storage space ability while lowering clutter. This enhanced company not just simplifies monitoring stock degrees yet also assists in more precise projecting and replenishment.Enhanced Room Usage

When organizations implement bulk storage remedies, they often experience considerable improvements in room utilization, which straight improves supply administration. By combining items into mass containers, firms make the most of vertical and horizontal storage capacity, decreasing squandered room. This efficient arrangement not only permits more inventory to be kept within the very same footprint however additionally assists in simpler access to products. The reduction of aisle space commonly required for smaller sized containers further optimizes warehouse formats. Additionally, mass storage remedies can suit a selection of product dimensions and shapes, making it easier to adjust to changing supply demands. Consequently, organizations can accomplish an extra reliable and well organized warehouse atmosphere, ultimately resulting in improved functional performance and decreased overhanging prices.Simplified Stock Tracking

Improved Transport Performance and Handling

As companies seek to improve their logistics operations, the fostering of mass containers arises as a pivotal method for improving transport performance and handling processes. These containers promote the movement of huge amounts of items, reducing the number of trips called for and ultimately lowering transport expenses. Their consistent shapes and size permit for optimized loading and unloading, lessening delay times at storehouses and ports. Additionally, bulk containers simplify taking care of by making it possible for making use of specialized tools, such as forklifts and automated systems, which boost rate and minimize labor expenses. By consolidating products right into less deliveries, business can also improve supply Reusable Bulk Plastic Containers monitoring and lower the danger of damages, eventually causing a much more efficient supply chain overall.Ecological Advantages of Using Mass Containers

Making use of bulk containers significantly adds to ecological sustainability within the supply chain. By minimizing packaging waste and promoting lasting material use, these containers aid lower the overall carbon impact related to transport and storage. This shift in the direction of mass options straightens with worldwide efforts to reduce environmental effect and improve resource performance.

Minimized Product Packaging Waste

Bulk containers significantly add to decreased product packaging waste, offering an engaging benefit for services and the atmosphere alike. By utilizing bulk containers, firms can decrease the quantity of product needed to package goods, causing much less total waste. Standard product packaging often involves several layers of materials, which can be both ecologically damaging and pricey. On the other hand, bulk containers settle items into less devices, minimizing the requirement for extreme covering, boxes, or containers. This improving not only reduces disposal costs however additionally simplifies recycling initiatives. On top of that, making use of long lasting, reusable mass containers enables services to adopt a much more sustainable strategy, promoting a culture of ecological responsibility. Inevitably, the shift to mass containers supports both operational performance and ecological conservation.Lower Carbon Impact

A substantial decrease in carbon footprint is just one of the key ecological benefits related to using bulk containers. These containers lessen the demand for extreme packaging products, which frequently add to waste and greenhouse gas exhausts during manufacturing and disposal. By transferring goods in bigger quantities, bulk containers minimize the variety of journeys called for, resulting in lower gas intake in logistics. This efficient transportation approach not only reduces carbon discharges yet also enhances supply chain operations. The sturdiness of mass containers assurances they can be recycled numerous times, in addition decreasing the environmental impact compared to single-use packaging. In general, the adoption of bulk containers plays a critical duty in advertising a more sustainable supply chain.

Sustainable Product Use

While benefiting sustainability, companies progressively transform to mass containers that utilize environment-friendly products. These containers, typically made from biodegradable or recycled compounds, greatly reduce ecological effect compared to conventional packaging. By reducing dependence on single-use plastics, mass containers contribute to squander decrease and promote a circular economic situation. Their resilient layout enables for multiple usages, improving resource performance. Business adopting these green options can also boost their brand image, interesting ecologically aware customers. Additionally, making use of sustainable products wholesale containers typically results in reduced energy usage during manufacturing, lining up with corporate sustainability objectives. Overall, the change towards lasting material use in bulk containers is an essential action in fostering a much more responsible supply chainSituation Researches: Successful Assimilation of Bulk Containers in Different Industries

Countless industries have actually successfully integrated mass containers into their supply chain procedures, boosting efficiency and minimizing costs. The food and drink industry has made use of mass containers to improve active ingredient storage space and transportation, reducing waste and enhancing inventory monitoring. In the chemical market, firms have actually adopted bulk containers to assist in much safer handling and storage space of hazardous materials, consequently increasing compliance with security policies. Furthermore, the automotive sector has actually implemented bulk containers for the transportation of components, reducing product packaging waste and improving assembly line efficiency. These case researches highlight just how bulk containers can not just enhance logistics yet likewise promote sustainability across various fields, ultimately leading to better source monitoring and raised productivity.Often Asked Concerns

What Kinds of Materials Are Generally Stored in Mass Containers?

Commonly, mass containers save materials such as grains, chemicals, metals, liquids, and accumulations. Plastic Bulk Containers. These containers accommodate numerous markets, assisting in the effective transport and storage space of large amounts of products, making certain structured handling and decreased wasteJust How Do Mass Containers Affect Product Top Quality During Transportation?

Bulk containers protect items from environmental variables, reduce contamination risks, and minimize activity during transport. Their robust building and construction assurances security, protecting item stability and top quality throughout the supply chain, eventually leading to improved consumer complete satisfaction.

What Are the Typical Sizes of Mass Containers Available?

Common sizes of mass containers usually consist of 40-foot and 20-foot containers, with capacities varying from 1,000 to 2,700 litres for intermediate bulk containers, fitting numerous items for efficient transportation and storage space solutions.Can Mass Containers Be Custom-made for Particular Products?

Yes, bulk containers can be personalized for details products. Different materials, dimensions, and designs are offered to satisfy one-of-a-kind demands, guaranteeing suitable defense and effectiveness during storage space and transportation of varied products.Just how Do I Pick the Right Bulk Container for My Demands?

To choose the best mass container, one must consider product characteristics, weight capability, material compatibility, and desired transportation method. In addition, examining storage area and regulatory demands will further guarantee the option fulfills details demands properly.Bulk containers offer enhanced efficiency by making best use of storage room and lowering the regularity of deliveries. Bulk containers greatly add to cost savings by lessening packaging materials and minimizing waste. In contrast, bulk containers settle items right into less devices, lowering the demand for extreme wrapping, boxes, or containers. Many sectors have successfully incorporated mass containers right into their supply chain operations, improving effectiveness and decreasing prices. Additionally, the automobile market has actually carried out bulk containers for the transportation of parts, reducing product packaging waste and boosting assembly line efficiency.

Report this wiki page